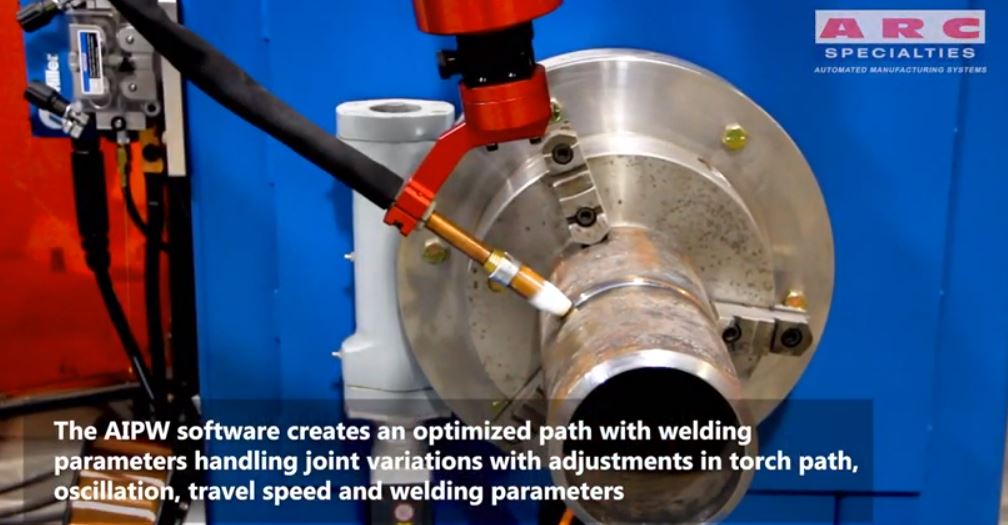

The AIPW uses a welding power supply to weld the root with Regulated Metal Deposition (RMD), then switches to pulsed spray for the fill and cap passes. This combination of Gas Metal Arc Welding techniques maximizes welding productivity while producing X-Ray quality, full penetration pipe welds.

ARC Specialties’ Artificial Intelligence Pipe Welding System (AIPW) incorporates the 6-axis UR5 collaborative robot arm from Universal Robots to carry out challenging welds in the oil & gas industry. “The UR5 now becomes our ‘golden arm’,” said Dan Allford, president of ARC Specialties. “The UR5 is small enough to be portable yet still allows full freedom of motion for both the laser scanner and welding torch. The robot is able to safely work in close proximity to humans.” The AIPW launched at the Offshore Technology Conference (OTC) in Houston.