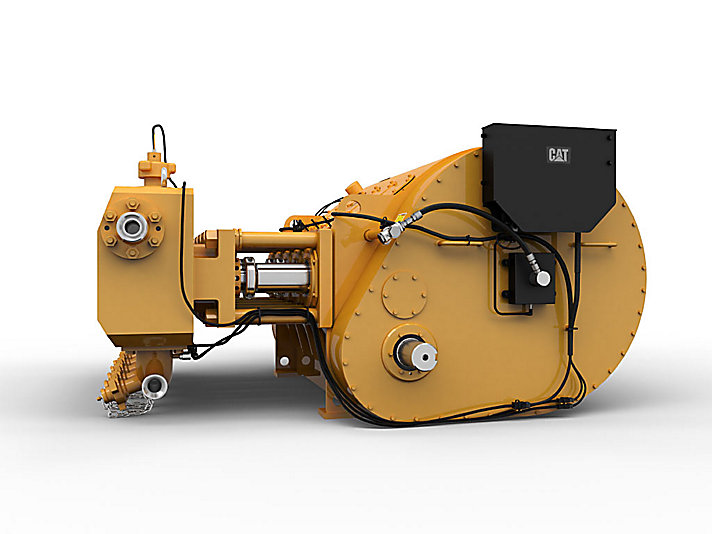

Warren CAT, the Caterpillar dealer for West Texas and Oklahoma, recently hosted an event in partnership with Caterpillar to display its new all-Cat frac trailer, which is equipped with all-Caterpillar components from the engine to the transmission, frac pumps and the technology.

“If you’ve ever been on a frac site, between jobs they take the engine to idle and it sets there. That wastes fuel and increases emissions. This has an automatic start-stop system that senses when the engine is idling and shuts it down.”

PUMP ELECTRONIC MONITORING SYSTEM

- PEMS detects failures before they happen. PEMS’ primary function is to analyze staggering amounts of data in real-time, looking for any signs of a possible failure state. This data is gathered through a comprehensive set of sensors including oil temperature, oil pressure, vibration, discharge pressure, and suction pressure sensors. Data gathered through these sensors is used in proprietary algorithms, and when they signal a possible failure, the operator is immediately alerted. These alerts are similar to the Public J1939 warnings and event data used in engines and transmissions. PEMS can also detect leakage and cavitation, which is a leading cause of fluid end wear.

- PEMS has been developed through extensive testing. Hydraulic fracturing is done differently all over the world, and testing pumps means pushing them into extremely high speeds and pressures. Gathering testing data is difficult as well, as every test results in mounds of it. These are significant obstacles for any team developing pump data monitoring, but Caterpillar has done the tough work for hydraulic fracturing operators. There’s no need for operators to manage all this data on their own. With PEMS, the operator brings the system online and responds as needed.

- PEMS is ready for retrofitting and can be used with Cat® or other pump brands. PEMS is effective with most brands and pump types, and, like most ECMs, is installed in an easy to access location. It takes little effort to integrate PEMS into existing pumps, and it will be an optional addition to new Cat pumps.

- PEMS is designed to be built upon. Already, PEMS is effective at avoiding common and costly failures, but Cat engineers are working on making it even better. Future versions of PEMS will also feature oil quality sensors, and it will eventually be paired with DTOC to make DTOC’s automated functions more precise and efficient. Currently, PEMS is ready for integration into Cat Connect systems, allowing fleet managers to respond to alerts and scheduled maintenance from remote locations, and from a single console.