Seismos used its non-invasive equipment suite (KView™) to acquire and deliver real-time data that enabled the operator to make on-the-fly decisions, while having no impact on operations. The instrumentation was minimal, surface-based, and non-invasive, while installation and operation of Seismos equipment did not cause any delays.

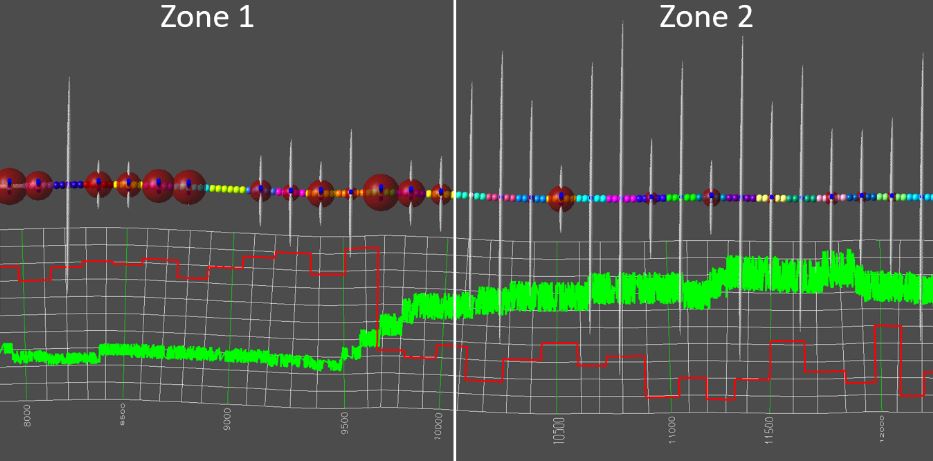

Seismos remotely interrogated the subsurface for each stage. Various properties such as near wellbore fracture conductivity, network complexity, effective fracture length, and far-field fracture network connectivity to the reservoir were computed.

C&J Energy Services, Seismos partner onh. C&J Energy Services is teaming with Seismos to collaborate on the industry’s first real-time hydraulic fracture characterization solution. – world oil One of the ten largest US operators (C&J Energy Services) asked Seismos to evaluate its treatment effectiveness and completion designs for the lower Wolfcamp A formation. The goals were to identify the types of fracture systems created across the lateral, and how such systems influence production. The project encompassed a two well pad and was completed in early 2018. Each lateral was composed of 45 stages and was treated with a single design.