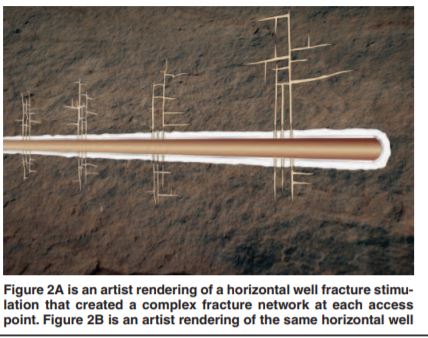

Refracturing often is considered the best option for combatting production declines in unconventional reservoirs. Decline rates from SRR wells usually are more rapid than wells in conventional reservoirs because of their ultralow permeability, limited reservoir contact, and the original completion strategy.

The success or failure of refracturing can have implications for field development.

The desire to reinvigorate wells by performing secondary or tertiary hydraulic fracture stimulation treatments has been present for many years. The need for improving production above the economic break-even point and tapping additional portions of the reservoir are lofty goals that have proven difficult,

if not impossible, to achieve in conventional reservoirs. Read more